Effect of Low Molecular Weight Oxidized Materials and Nitrogen Groups on Adhesive Joints of Polypropylene Treated by a Cold Atmospheric Plasma Jet

Kateřina Polášková, Miloš Klíma, Zdenka Jeníková, Lucie Blahová, Lenka Zajíčková

Polymers 13 (2021) 4396

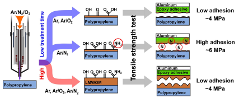

Polypropylene is a typical representative of synthetic polymers that, for many applications including adhesive joints, requires an increase in wettability and chemical surface reactivity. Plasma processing offers efficient methods for such surface modifications. A particular disadvantage of the plasma jets can be the small plasma area. Here, we present a cold atmospheric plasma radio-frequency slit jet developed with a width of 150 mm applied to polypropylene plasma treatment in Ar, Ar/O2 and Ar/N2 We identified two main parameters influencing the tensile strength of adhesive joints mediated by epoxy adhesive DP 190, nitrogen content, and the amount of low molecular weight oxidized materials (LMWOMs). Nitrogen functional groups promoted adhesion between epoxy adhesive DP 190 and the PP by taking part in the curing process. LMWOMs formed a weak boundary layer, inhibiting adhesion by inducing a cohesive failure of the joint. A trade off between these two parameters determined the optimized conditions at which the strength of the adhesive joint increased 4.5 times. Higher adhesion strength was previously observed when using a translational plasma gliding arc plasma jet with higher plasma gas temperatures, resulting in better cross linking of polymer chains caused by local PP melting.

Effects of additives on atmospheric pressure gliding arc applied to the modification of polypropylene

Petr Jelínek, Kateřina Polášková, Filip Jeník, Zdenka Jeníková, Lukáš Dostál, Eva Dvořáková, Jiří Cerman, Hana Šourková, Vilma Buršíková, Petr Špatenka, Lenka Zajíčková

Surface and Coatings Technology 372 (2019) 45-55

DOI: 10.1016/j.surfcoat.2019.04.035

The polypropylene (PP) strips were modified with the industrial gliding arc discharge working in air flow at 50 Hz. The experiments aimed at increased wettability and improved strength of the epoxy adhesive DP190 bond with PP. While working only in dry air, the deterioration of the plasma treatment uniformity was observed at higher treatment speeds than 100 mm/s. At the same time, the tensile strength of the adhesive bond and the atomic concentrations of O and N decreased whereas the water contact angle (WCA) measurement error increased. The fast camera measurements revealed that the PP surface was treated by the direct contact with active plasma filaments. The non-uniformity of the PP surface treatment for increased treatment speed can be explained by taking into account the stochastic character of the filament propagation direction and the characteristic time scales of the process. As an improvement of the gliding arc treatment technology a new geometry utilizing the gas cross flow was proposed with the help of gas dynamic simulations. The addition of argon cross flow led to an improvement of the treatment uniformity and, for the optimized conditions, the measured tensile strength of the adhesive bond to PP was 6.5 times higher than for the untreated PP sample. The treatments with the cross flow of argon mixed with water vapors and volatile organic compounds (VOCs), ethanol and isopropanol, did not increase the tensile strength of the adhesive joint even though the wettability was higher for the mixtures with VOCs. Since the concentration of functional groups measured by X-ray photoelectron spectroscopy was well correlated with the tensile strength of adhesive joints, WCA measurements cannot be used as the only parameter judging the success of the plasma treatment aimed at an improvement of adhesive joint strength.

The transport and surface reactivity of O atoms during the atmospheric plasma etching of hydrogenated amorphous carbon films

Mohamed Mokhtar Hefny, David Nečas, Lenka Zajíčková, Jan Benedikt

Plasma Sources Science and Technology 28 (2019) 035010

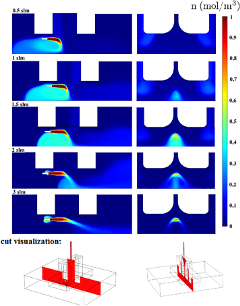

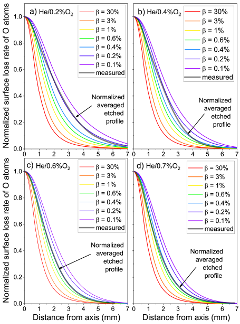

A remote microscale atmospheric pressure plasma jet (μAPPJ) with He/O₂ gas mixture is used to etch a hydrogenated amorphous carbon layer. The etched profiles are measured by means of imaging spectroscopic reflectometry, a powerful technique providing a 2D map of the film thickness (etched profile) and also film properties. Additionally, 2D axially symmetric fluid model of the gas flow and species transport combined with the basic kinetic model of the reaction of O atoms with O₂ molecules has been solved to study the transport and surface reactivity of O atoms. The model provides spatially resolved and surface-integrated O atom loss rate at the surface. The situation with convection-dominated species transport and fast recombination reactions of O atoms in the volume leads to a strong dependence of the etched profile on the O₂ admixture and O atom surface loss probability β. By comparing etched profiles with the simulation results, the O atom surface reaction probability of β=0.2–0.6% could be estimated. The modeled O atom loss rate at the surface was always higher and with the same trend as the etching rate, corroborating that O atoms are the main etching species. The presented data and simulation results show that the fastest surface-integrated etching rate is achieved not under conditions with the highest O density on the jet axis, but at lower O₂ admixtures due to reduced recombination losses in the gas phase.

Liquid assisted plasma enhanced chemical vapour deposition with a non-thermal plasma jet at atmospheric pressure

Jan Schäfer, Katja Fricke, Filip Mika, Zuzana Pokorná, Lenka Zajíčková, Rüdiger Foest

Thin Solid Films 630 (2017) 71-78

DOI: 10.1016/j.tsf.2016.09.022

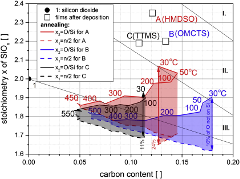

The present study introduces a process for the synthesis of functional films onto substrates directly from the liq- uid phase. The reported method is based on the initialization of the synthesis by means of an atmospheric pres- sure plasma jet operating with argon above a thin liquid film of the starting material. The process is demonstrated by the formation of a thin, solid SiO x film from siloxane-based liquid precursors. Changes in the chemical prop- erties of the precursor were studied in-situ during the polymerization process on the diamond crystal by using Fourier transform infrared spectroscopy The elemental composition of the SiO x C y films was analyzed by X-ray photoelectron spectroscopy (XPS). Furthermore, XPS was applied to study the effect of post-annealing processes on the composition of the films. The obtained deposits exhibit a low concentration of carbon groups. The amount of hydroxyl groups and interstitial water can be reduced significantly by post-process annealing of the films.