Deposition Penetration Depth and Sticking Probability in Plasma Polymerization of Cyclopropylamine

Miroslav Michlíček, Lucie Blahová, Eva Dvořáková, David Nečas, Lenka Zajíčková

Applied Surface Science 540 (2021) 147979

DOI: 10.1016/j.apsusc.2020.147979

Understanding the role of substrate geometry is vital for a successful optimization of low-pressure plasma polymerization on non-planar substrates used in bioapplications, such as porous materials or well plates. We investigated the altered transport of film-forming species and properties of the coatings for a cyclopropylamine and argon discharge using a combined analysis of the plasma polymer deposition on flat Si pieces, culture wells, microtrenches, a macrocavity, porous hydroxyapatite scaffolds and electrospun polycaprolactone nanofibrous mats. The aspect ratio of the well structures impacted mainly the deposition rate, whereas the film chemistry was affected only moderately. A large deposition penetration depth into the porous media indicated a relatively low sticking probability of film-forming species. A detailed analysis of microtrench step coverage and macrocavity deposition disproved the model of film-forming species with a single overall sticking probability. At least two populations with two different sticking probabilities were required to fit the experimental data. A majority of the film-forming species (76%) has a large sticking probability of 0.20±0.01, while still a significant part (24%) has a relatively small sticking probability of 0.0015±0.0002. The presented methodology is widely applicable for understanding the details of plasma-surface interaction and successful applications of plasma polymerization onto complex substrates.

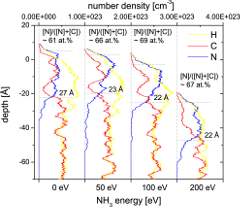

Molecular dynamics simulation of amine groups formation during plasma processing of polystyrene surfaces

Miroslav Michlíček, Satoshi Hamaguchi, Lenka Zajíčková

Plasma Sources Science and Technology 29 (2020) 105020

Plasma treatment and plasma polymerization processes aiming to form amine groups on polystyrene surfaces were studied in-silico with molecular dynamics simulations. The simulations were compared with two experiments, (i) plasma treatment in N2/H2 bipolar pulsed discharge and (ii) plasma polymerization in cyclopropylamine/Ar radio frequency (RF) capacitively coupled discharge. To model favorable conditions for the incorporation of primary amine groups, we assumed the plasma treatment as the flux of NH2 radicals and energetic NH3 ions, and the plasma polymerization as the flux of cyclopropylamine molecules and energetic argon ions. It is shown in both the simulation and the experiment that the polystyrene treatment by the bipolar pulsed N2/H2 plasmas with an applied voltage of about ±1 kV formed a nitrogen-rich layer of a thickness of only a few nm. The simulations also showed that, as the NH3 incident energy increases, the ratio of primary amines to the total number of N atoms on the surface decreases. It is because the energetic ion bombardment brakes up N–H bonds of primary amines, which are mostly brought to the surface by NH2 radical adsorption. Our previous experimental work on the CPA plasma polymerization showed that increased RF power invested in the plasma leads to the deposition of films with lower nitrogen content. The MD simulations showed an increase of the nitrogen content with the Ar energy and a limited impact of the energetic bombardment on the retention of primary amines. Thus, the results highlighted the importance of the gas-phase processes on the nitrogen incorporation and primary amines retention in the plasma polymers. However, the higher energy flux towards the growing film clearly decreases amount of hydrogen and increases the polymer cross-linking.

Homogeneity and Penetration Depth of Atmospheric Pressure Plasma Polymerization onto Electrospun Nanofibrous Mats

Miroslav Michlíček, Anton Manakhov, Eva Dvořáková, Lenka Zajíčková

Applied Surface Science 471 (2019) 835–841

DOI: 10.1016/j.apsusc.2018.11.148

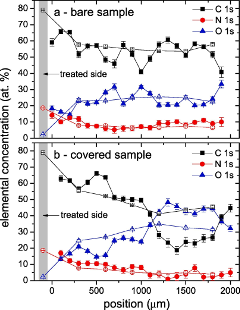

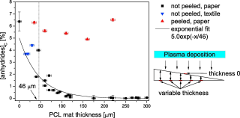

This work investigates for the first time the penetration depth, nanoscopic homogeneity and conformality of the plasma polymerization onto an electrospun nanofibrous mat. The study is carried out on the model example of atmospheric pressure plasma co-polymerization of anhydride-rich films onto polycaprolactone mats that can find a significant practical applications, for example in tissue engineering and regenerative medicine. Since the surface-to-volume ratio of nanofibrous mats is enormous and the structure of mats resembles extracellular matrix the successful plasma coating of each whole fiber and understanding the penetration of the polymerization into the mat structure are extremely important. The films with reactive anhydride groups were prepared by co-polymerization of maleic anhydride and acetylene using dielectric barrier discharge. The studies were accompanied by the quantification of anhydride groups directly on the PCL electrospun mat using the chemical derivatization with trifluoroethylamine and X-ray photoelectron spectroscopy. The nanoscopic homogeneity and conformality of the anhydride plasma polymer coating on the front side and backside of the nanofibrous mat, 30–40 um in thickness, did not differ according to the dynamic SIMS mapping. The films containing approximately 6 anhydride groups per 100 carbon atoms coated homogeneously the nanofibers deeper in the PCL mat. The characteristic penetration depth of the deposition was estimated as 46 +- 5 um.